The why, where & how of FSC timber in Australia

[Above] Associate William Cassell presenting at the Melbourne Regenerative Design Forum, held at COX’s Melbourne Studio. Photography: Chris Buntine (Atelier Ten)

On Wednesday 1 May, COX hosted the Melbourne Regenerative Design Forum for a fascinating deep dive into all things FSC. From the certification process and benefits of specifying Forest Stewardship Council certified timber, to planning for biodiversity and circularity, the panel provided a roadmap for practitioners to better understand sustainable wood and its application in the built environment.

COX Associate William Cassell was joined by Stefan Jensen (FSC Australia and New Zealand), Nick Capobianco (SCS Global Services), Joe Ballester (Abodo Wood) and Ed Bond (Robert Bird Group) as well as moderator Chris Buntine (Atelier Ten).

“Choosing FSC certified materials for our buildings might seem daunting at first, especially if our teams lack the right information,” explains Laura Turner, COX’s National Regenerative Design Leader.

“However, this event proved to be an incredible chance to demystify the process. We heard from a diverse group of experts – the certifier, manufacturer, structural engineer and architect – who showed us that sourcing these materials can be straightforward when we know who to speak to and where to look. It was an inspiring opportunity to learn and make more informed choices together!”

L-R: Joe Ballester (Abodo Wood), Nick Capobianco (SCS Global Services), Ed Bond (Robert Bird Group), Stefan Jensen (FSC Australia and New Zealand), William Cassell (COX)

Some key takeaways included:

- Simply swapping from concrete structure to timber structure is not enough to ensure a sustainable outcome – practitioners should ensure that products are sustainably sourced with embedded traceability and a society and governance first culture. This reduces project risk and ensures environmental and social benefits are not diminished. Find FSC certified sites and products, or check manufacturer’s FSC claims here.

- Very few Australian forests have been able to achieve FSC certification, despite multiple attempts. As designers, we need to gain a better understanding of the true impact of the timber we specify, particularly Australian hardwoods like blackbutt, spotted gum and other eucalypts.

- Technology continues to change the ways in which we apply timber in projects and R&D is a major investment. For example, Abodo Wood’s thermally modified Vulcan Cladding provides an FSC certified renewable alternative to Western Red Cedar.

- We can also look to the past to inspire future innovation. William discussed the contemporary method of installing timber floorboards – with glue rather than nails – as a key barrier to their re-use and of circularity in buildings. Enabling the circular economy goes beyond specifying a sustainable material source.

- To overcome potential challenges in ensuring FSC products make it into projects, practitioners should be well informed, choose specific FSC products, understand lead times, check in with contractors to ensure the Chain of Custody is unbroken, and request sales invoices, which must clearly state which products are FSC certified.

- FSC certified materials aren’t always more expensive, but including them in early design phase material schedules, and being specific about the species, can help ensure there are no unforeseen costs.

- While the FSC market is relatively small in ANZ compared to Europe, big projects have the potential to act as levers for smaller local forestry organisations and manufacturers to achieve FSC certified products.

- Beyond timber, anything that grows in a forest can be FSC certified including rubber, mushrooms, honey, seeds and bamboo! Construction projects – or part of – can also be FSC certified, not just products.

It’s no surprise that designers love using timber for its warmth and many biophilic and sustainability benefits. However, in the face of growing demand and with appreciation for the myriad of ecological, hydrological and climate system benefits that trees in forests bring, it should be “considered a precious resource, just as we think of gold,” explained William. Aligned with COX’s deeply ingrained ‘Do More, With Less’ core value, “we aim to do as much as we can, with as little as possible,” he continued.

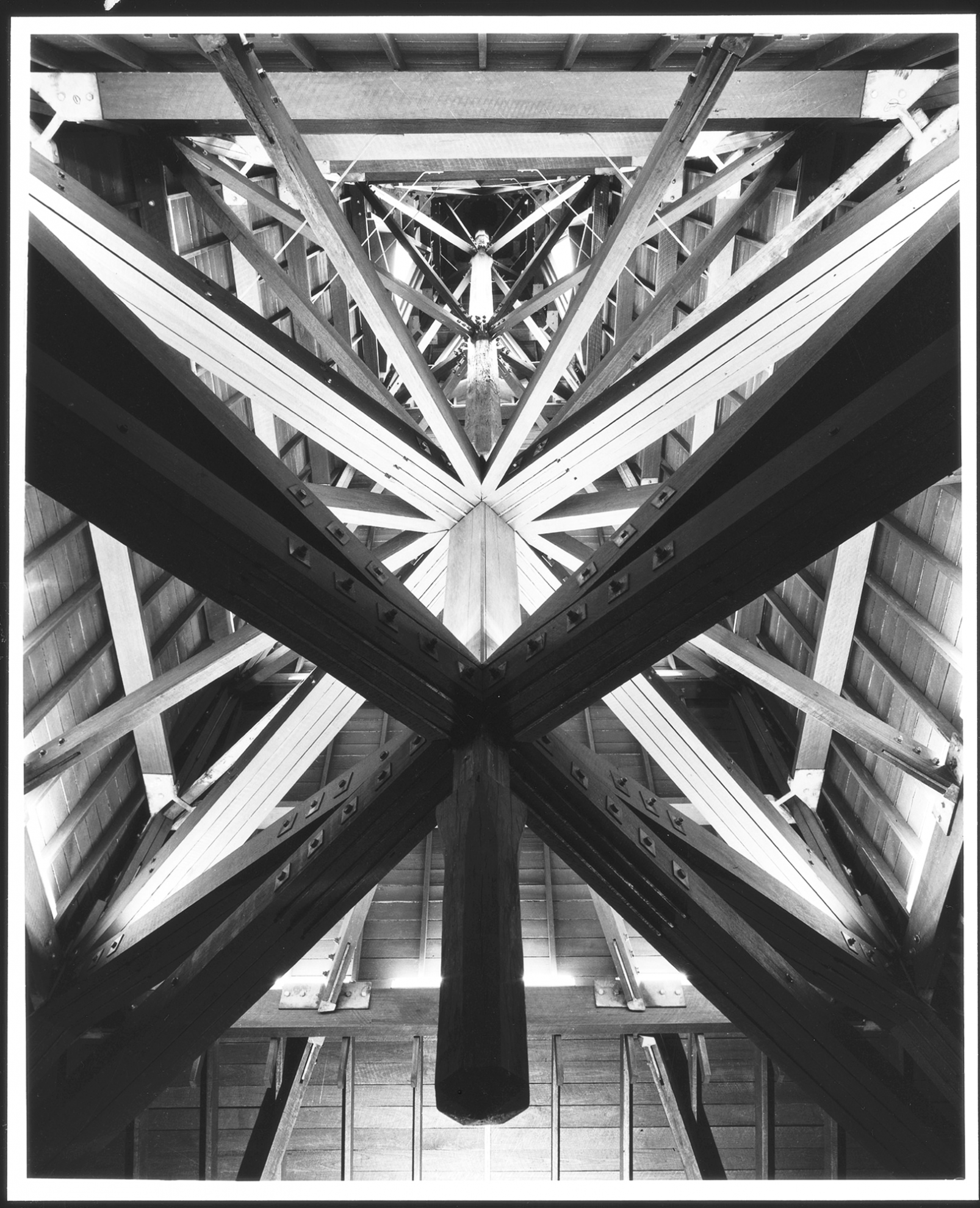

At CB Alexander College (now Tocal College), one of the earliest projects undertaken by the practice, the dormitory and teaching buildings are interconnected by colonnades crafted from heavy baulks of Brushbox. These timbers are also used for interior expressed structure and custom-designed furniture. Discover more

More recently, the structure of COX’s Wurriki Nyal Civic Precinct in Geelong utilised FSC certified glulam timber, and locally grown and manufactured CLT with a PEFC/Responsible Wood certification. The Precinct is designed to embody The City of Greater Geelong’s aspirations for its community and reflect attributes that are uniquely Geelong. The building achieves 6-Star Green Star and NABERS ratings, creating a light-filled and healthy contemporary workplace. Discover more

A big thank you to MRDF for the opportunity to host this event and to all the architects, designers, engineers, sustainability consultants and others who attended, it was great to welcome you into our Melbourne studio and online.

About MRDF

This event is part of an on-going series run by the Melbourne Regenerative Design Forum, a collective or organisations seeking to bring people together to catalyse conversations on how we can bring regeneration to the built and natural environment.

About FSC

The Forest Stewardship Council unites individuals, businesses, governments and NGOs under a common goal: protecting healthy, resilient forests for all, forever.

[below] Stefan Jensen, Policy and Standards Manager, FSC Australia and New Zealand